Polymers that undergo chromatic transitions based on heating and cooling elements are referred to as being thermochromatic and are perhaps the most studied materials in chemical plastic technologies. Spectral data is often used to monitor the changes in these materials to determine suitability for various product applications. These products are created by adding color-changing plastic masterbatches to standard plastic materials during the injection molding or extrusion process to alter the finished product, making it suitable for a variety of applications. By utilizing spectral data, researchers can evaluate the effectiveness of these materials under different conditions forging the way for new technologies such as body temperature monitoring medical supplies, climate data integration equipment, environmentally-friendly building materials, and even practical applications in food service products.

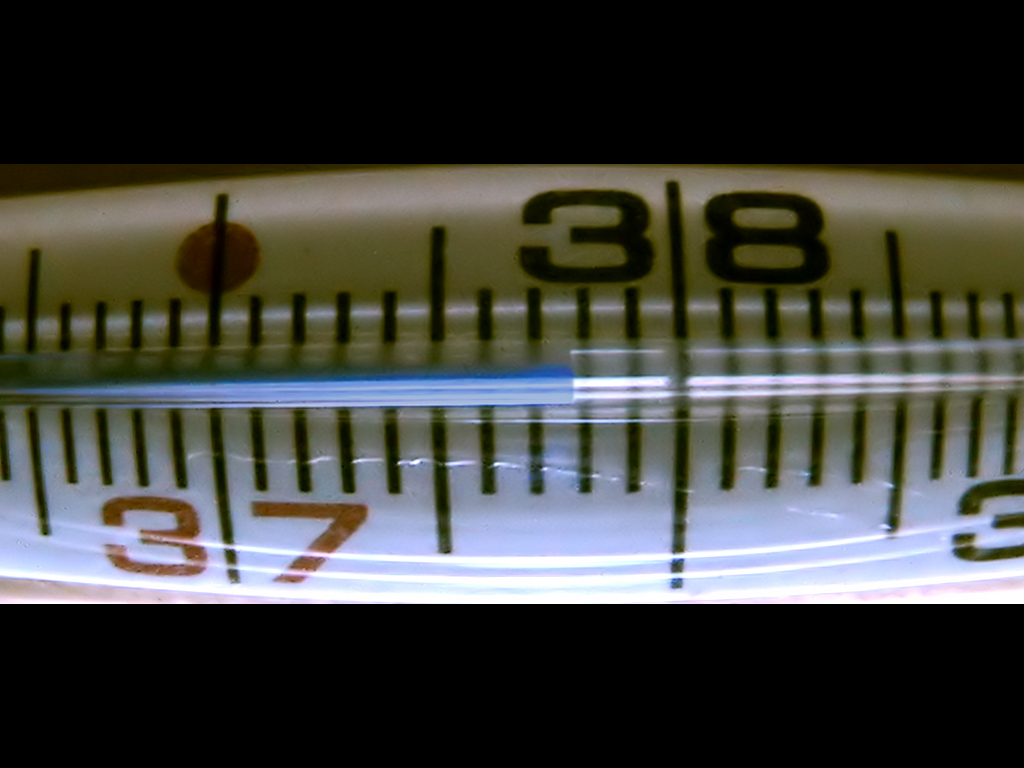

Spectrophotometers take a closer look at the chameleon-like thermochromic properties in polymer materials. Image Source: Flickr user Umberto Salvagnin