The effect of light on an object can change its color appearance significantly. Perhaps you remember the notorious “Is That Dress White and Gold or Black and Blue?” debate-turned-viral phenomenon at the beginning of the year. Many people were surprised at how drastically color perception could change based on lighting alone. However, this is not a new phenomenon. Color measurement instrumentation has been used to address the issue of difference in color perception for decades. In particular, spectrophotometry can measure the effects of direct and indirect light by controlling the light source and quantifying true color in a controlled environment. This technology reduces visual discrimination and ensures color consistency in a number of industrial applications.

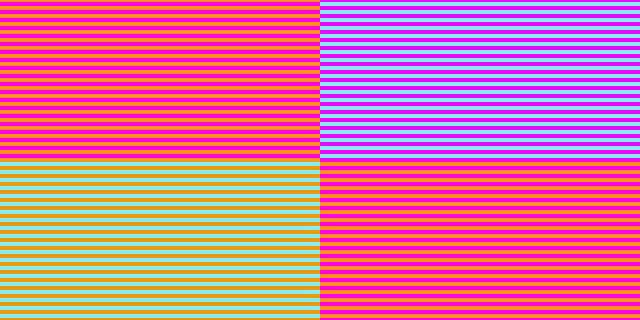

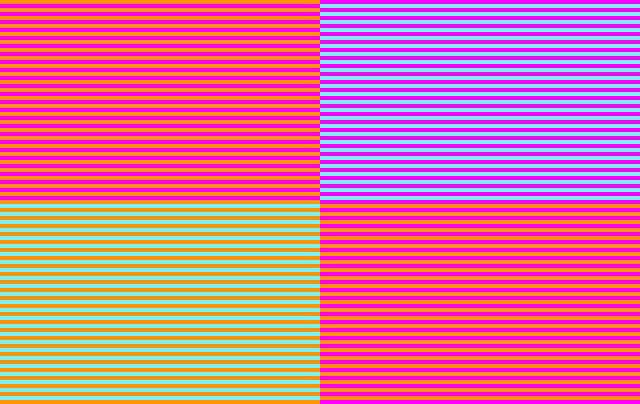

In the image above, the blue lines in the top right corner are exactly the same color as the green lines at the bottom left. This represents how color perception and visual discrimination can be altered greatly by various elements.

Image Source: Flickr user Robson#