The world of 3D color printing is exploding with new possibilities, and as new options in design and technology progress, the need for more advanced color measurement systems will need to accompany this growth. As instrumentation becomes more affordable and material supplies continue to expand, spectrophotometers provide the most versatile and precise method for color measurement and matching technology, allowing 3D printing capabilities to reach new heights in reproduction no matter what raw materials or color additives are used.

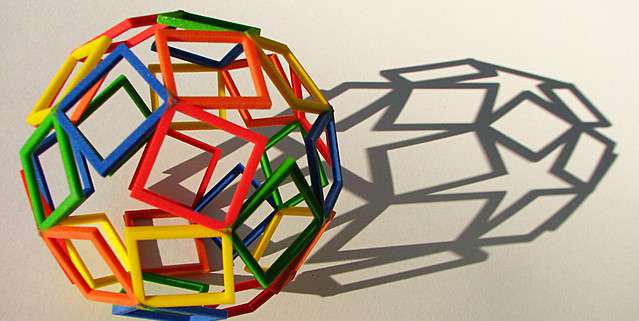

3D printing technology has opened the door to many new possibilities. Nearly any shape, size, or color can be reproduced with the right instrumentation. Image Source: Flickr user fdecomite