Chemical analysis is an intricate part of our everyday lives. From the water we drink to the food we eat to the fuel we put into our car, nearly everything we consume has undergone some form of chemical analysis before use. Although it’s likely not something we consider as we go about our daily activities, it’s a vital aspect of the production process for many things and something we all rely upon for quality assurance.

Petrochemical manufacturers know that chemical analysis is one of the most important steps in the monitoring of chemical compounds in the petroleum refining process. It is also one of the most unique and difficult processes to quantify and analyze. The ability to detect color changes is an important step in the process for identifying contaminants and impurities. With the right technology, the challenges of chemical analysis can be met.

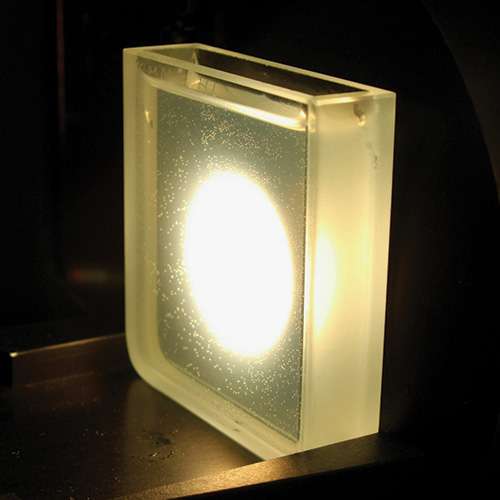

Clear liquids are classified based on visual comparison.

Applications of Color Measurement in Petrochemicals

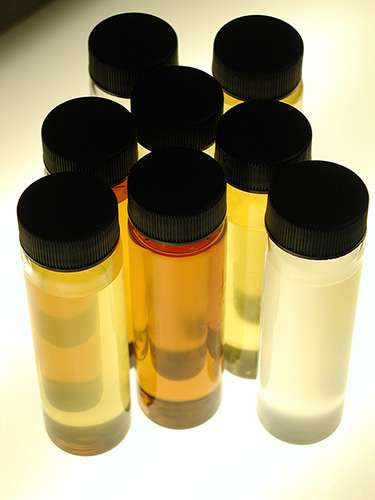

Petrochemical production results in a number of goods and materials that are dependent on accurate chemical analysis. From crude oil to the most refined petrochemical products, the manufacturing process relies on color technology to help with interpreting data, differentiation, and classifying petrochemical compounds. Petrochemical materials cover a wide range of products such as solvents, adhesives, plastics, resins, fibers, elastomers, lubricants, and gels. Each compound can vary from transparent to translucent to opaque, and accurate measurement is contingent upon the highest quality of instrumentation to measure transmittance or reflective materials.

The products that result from petrochemicals are numerous and varied. Image Source: Flickr user snowlepard

The petrochemical industry has greatly benefited from the use of color technology and spectrophotometers, and the ability to detect color changes throughout the refining process is an important step in identifying possible contamination. The ability to recognize even the slightest changes throughout processing helps to alleviate any impurities that may affect the quality of the final product. Detecting changes is crucial in monitoring and identifying any needs for re-distillation throughout the refining process.