Preforms are one of the fastest growing markets in the plastics industry and color technology serves a viable role in monitoring quality and consistency in these products. Preform plastics make up a variety of products used to package beverages, detergents, condiments, and many other packaging materials. Using an injection molding system, these products are stretch blow molded1 and inflated into the various shapes necessary for product development. Color technology enables manufacturers to monitor the color of raw plastic materials and predict final color outcome based on spectral data and analysis. Based on transparency and reflectance values, different color technology measurement systems are required to ensure product quality and consistency.

Color monitoring and control in plastic materials ensures final product color consistency and acceptability.

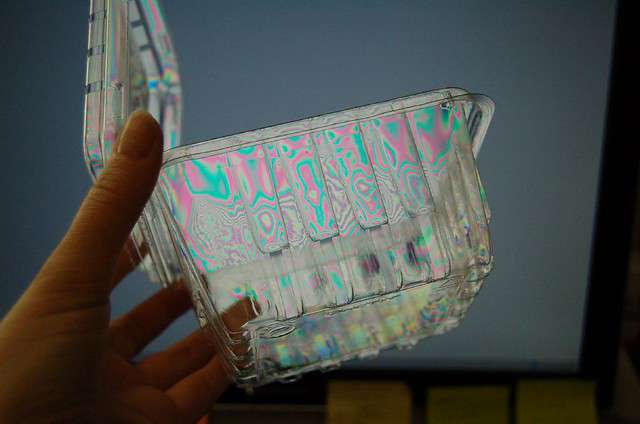

Image Source: Flickr user Reciclado Creativo