We all know that smell is an enormous factor in taste (if you don’t believe that, try smelling bacon without eating the whole package). It’s less well-studied, though inherently intuitive, that the visual aspect of food plays a huge role in shaping our perception of it . A child will recoil from a goulash, even if they like all the component parts. We automatically judge food, correctly or otherwise, by sight. If it doesn’t appeal to taste, smell, and vision, we are less likely to try it. This poses a challenge for food producers.

Ensuring the health of a brand means delivering consistent product quality that appeals to all of their customers’ senses. When it comes to appearance, color plays a key role in a food’s appeal, and making use of a spectrophotometer for food color measurement can ensure consistency and quality in a product. And with the way food must be moved from producer to factory to distributor to retailer, maintaining that color consistency at each location can be achieved by using a technique called hitch standardization.

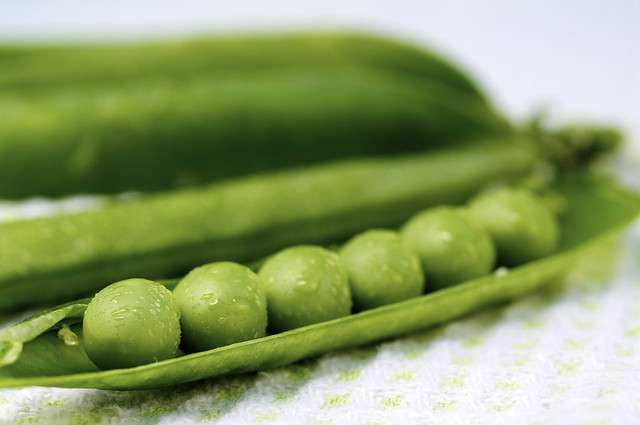

Measuring color with a spectrophotometer at each step of a vegetable’s journey from harvest to the retailer can help a food producer maintain quality control. Image source: Flickr user Nick Harris1