No one likes the idea of waste piling up in our landfills, but the financial impact of losing valuable materials is often the driving force that fuels the need for instrumental analysis. Color control plays a vital role in managing material usage and maintaining quality and consistency in a variety of manufactured goods. With appropriate color measurement instrumentation, the average business can save thousands while delivering the quality and value expected of their products.

Instrumental analysis has infiltrated nearly every consumer driven industry imaginable. From automobile parts and building materials to paints and plastics, spectrophotometers are the leading technology used for color measurement and quality control. “Any manufacturer of consumer products…should implement stringent quality controls to ensure that the first run matches required color specifications and that each successive lot is consistent. To do otherwise risks significant scrap and rework, delayed shipments, lot recalls, and loss of profits, if not valuable business relationships and contracts.”1 The benefits of instrumental analysis are undeniable, yet not all spectrophotometers are created equal. Advancements in technology have created a wide range of choices in color measurement tools, and developing an understanding of these options will help you make the most of your investment.

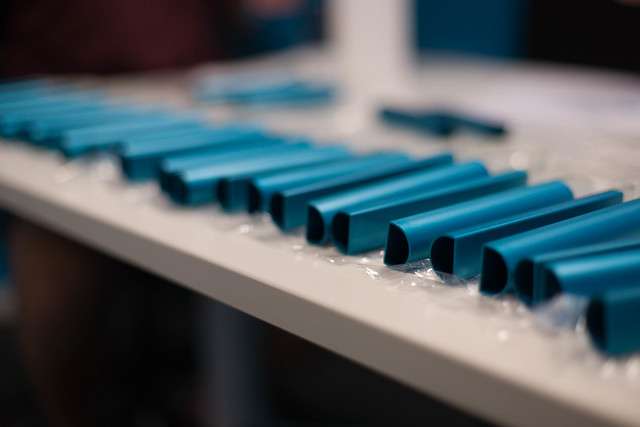

Color measurement instrumentation ensures consistency from lot to lot, reducing wasted materials and ensure product quality. Image Source: Flickr user garlandcannon