Plastic plaques are the basis of industry standards when manufacturing and developing colored plastic products. Quality perception in the plastic industry is significantly impacted by color consistency between product manufacturing and development. In high-volume production, customer satisfaction is dependent on maintaining color consistency and uniformity from the production line to consumer usage.

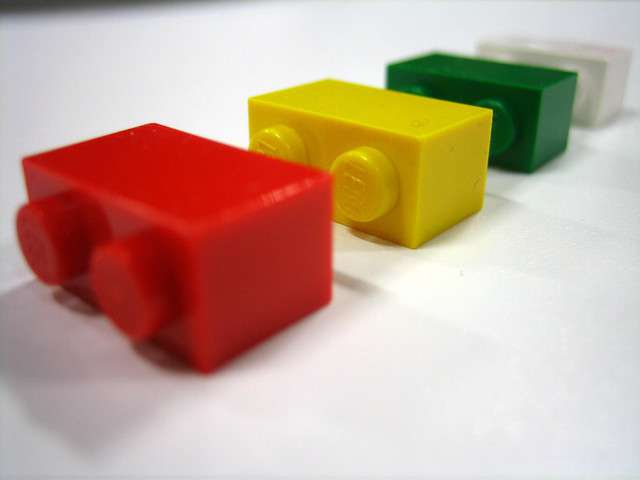

Plastic manufacturing and production depends on advanced color measurement systems to maintain consistency and quality in product development. Image Source: Flickr user Dave Bleasdale

The process of pressing plastic plaques is necessary for creating a standard for color selection in sample materials. However, maintaining color consistency between pressed samples and raw pellet materials requires the use of advanced technology and color measurement instrumentation. As materials are pressed and heated, it is important to use the right instrumentation to maintain color consistency between each sample and projected product color development. By understanding spectral analysis and utilizing the appropriate geometries and tools, color consistency and consumer satisfaction are attainable.