In the dynamic world of plastics manufacturing and recycling, precision matters. HunterLab’s color measurement solutions play a pivotal role in ensuring that every hue, shade, and tint aligns with quality standards.

In the dynamic world of plastics manufacturing and recycling, precision matters. HunterLab’s color measurement solutions play a pivotal role in ensuring that every hue, shade, and tint aligns with quality standards.

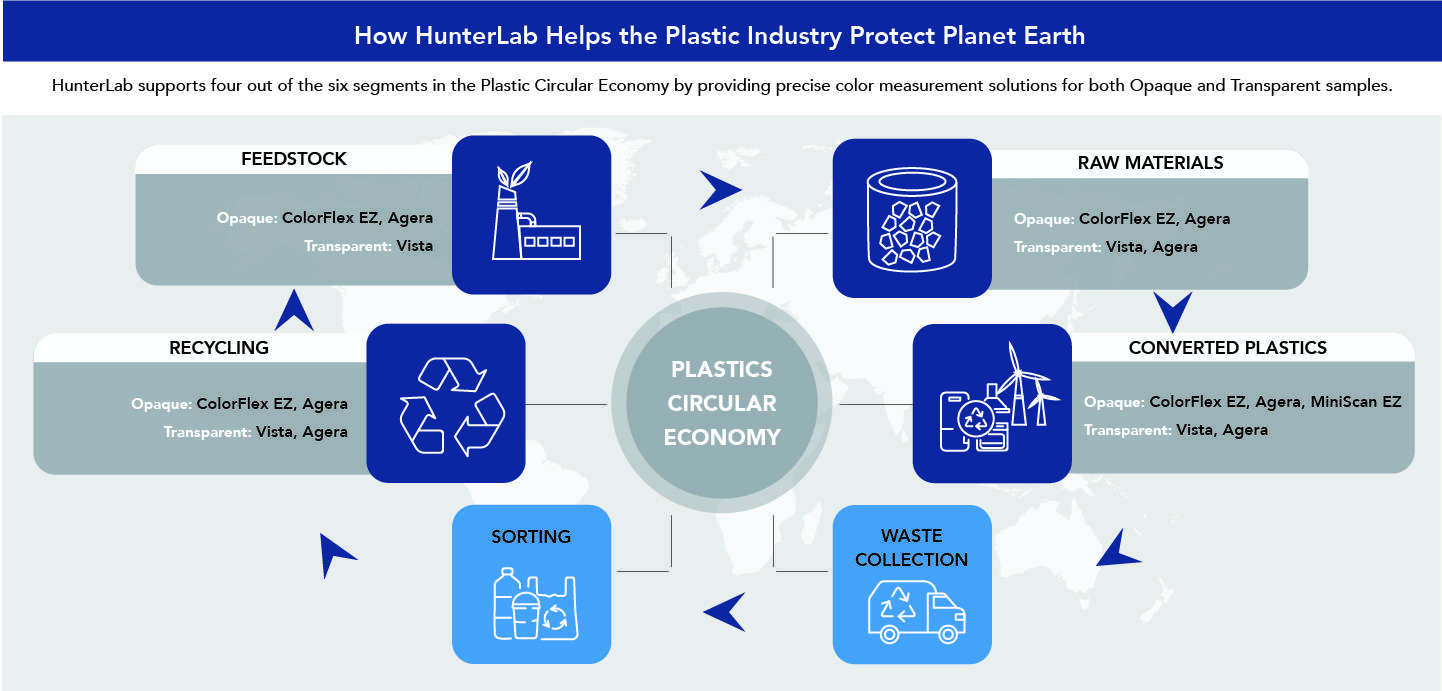

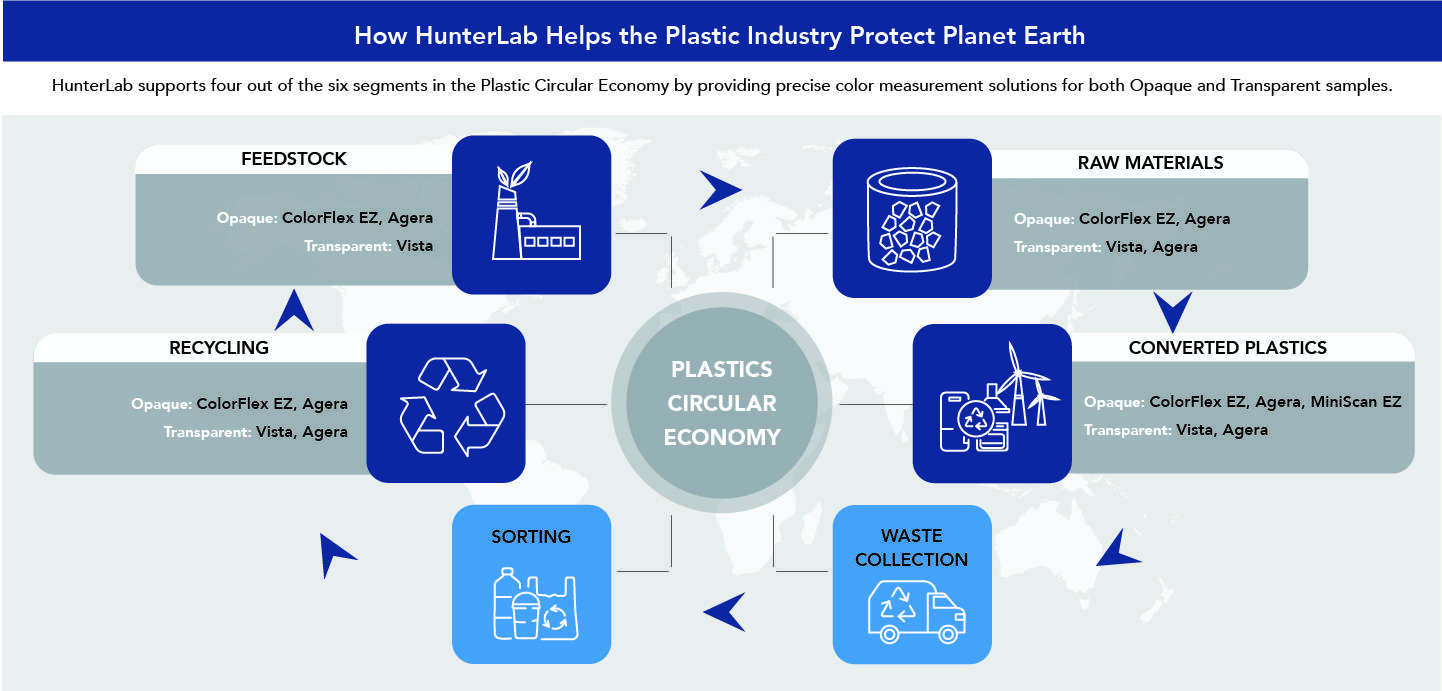

Let’s delve into how these solutions contribute to the Circular Economy, offering critical color measurement approaches in the end-to-end process, and our clients’ ESG objectives:

In summary, HunterLab’s color measurement solutions play a crucial role in achieving energy sustainability and governance objectives. By catching color problems early, minimizing waste, and promoting a circular economy mindset, companies can enhance their environmental performance and contribute to a more sustainable future.

HunterLab goes beyond color, delivering precise, science-backed solutions that help industries achieve superior quality and appearance control. As a global leader in spectrophotometry, we empower businesses to reduce waste, improve efficiency, and enhance product consistency—directly impacting the bottom line. By combining innovation, real-world expertise, and sustainable measurement solutions, we help manufacturers optimize production, minimize material loss, and meet the highest industry standards. Follow us on LinkedIn