Quality Paintballs Require Vibrant, Water-Based Dye

To manufacture quality paintballs, you need to find a delicate balance between color vibrancy and washability. Generally, the fill inside of a paintball is made from a water-soluble dye surrounded by polyethylene glycol.2 Because the dye is water-soluble, it can be washed off fairly easily, which is ideal for paintball enthusiasts who need a fresh, paint-free set of camouflage clothes every time they play. However, if you make your paintballs too water-soluble or washable, you risk creating a product that most competitive paintballers will find useless. It’s too easy to wipe these types of dyes off of your paintball gear before it has the chance to settle. Some paintball players cheat by wiping off poorly-made paintball dye before anyone sees that they were hit.

While lower-quality paintballs use dull, oil-based colors that are naturally slippery and easier to wipe off, high-end paintballs never use oil as a base for their colors. Instead, quality paintball manufacturers use deeply pigmented, non-toxic water-soluble dyes that will cling more strongly to clothes without permanently staining them. In order to find the best ingredients possible for your paintballs, you’ll first need to measure the vibrancy of these water-soluble dyes using a color spectrophotometer. Many spectrophotometers can measure the precise color of your paintball fill, as well as its opacity. Your goal is to create a paintball fill that is completely opaque, even when spread in a relatively thin layer, but that still washes off in a washing machine.3

Test Your Paint Colors Against Camouflage

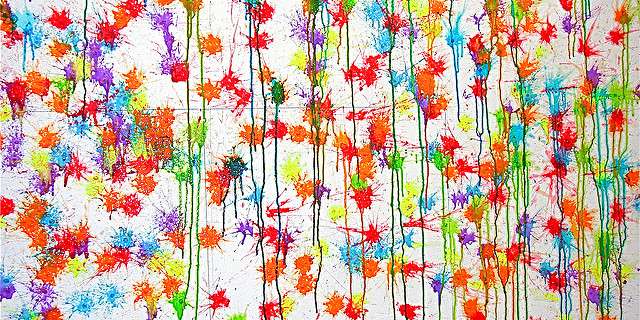

Once you’ve found the most opaque dyes for your paintball fill, you’ll also want to test these colors against some of the most popular camouflage patterns on the market. Most serious paintball competitions require players to wear dark clothing, so you should begin by testing a thin swatch of your paintball fill against a dark sample background. Using a color spectrophotometer, you can easily see whether your paintball fill lost opacity or color vibrancy after being spread against a dark piece of cloth. Most bright, neon colors, such as orange, yellow or red, will contrast well against a dark sample background—this is also why most paintballs are made using one of these three colors.4

However, other colors, like purple, blue or certain shades of green, may not show up as easily against purple, blue, and green backgrounds. This is why it’s especially important to test these three shades using a color spectrophotometer. You may find, for instance, that your neon purple paintball dye appears vibrant when it bursts open on a white background, but when it hits a dark green or black camouflage jacket, the purple isn’t as visible. The complex pattern on some camouflage jackets may also disguise your paintball colors. Your best insurance against dull paintballs is to test all of your colors using a color spectrophotometer in advance and to observe how each new color formula performs against a variety of camouflage backgrounds. As an added benefit, if you manage to create consistent, truly vibrant versions of relatively rare paintball colors, like purple or blue, you may attract more customers in the process.