Spectrophotometers Assess the Oxidation of Tea Leaves

In today’s world, more than coffee, more than beer, more than Coca-Cola, tea is King (it sure isn’t George III anymore). Having played a major role in global affairs for centuries, tea still thrives as the second most consumed1 beverage in the world, behind water. The resulting enormous volume of tea grown, imported, and processed requires highly efficient processes. Fast, reliable quality control is essential for manufacturers, to keep deliveries on time and up to specification. That’s why manufacturers often rely on spectrophotometers to quickly and accurately assess the color of their tea leaves.

Manufacturers measure the color of their leaves because color is indicative of the oxidation stage of a tea leaf. The oxidation of a tea leaf2 indicates of the final properties of a cup of tea, including color, flavor, and caffeine content. This is because all tea is made from the leaves of the same plant, Camellia sinensis. Green tea, black tea, white tea, and red tea are only differentiated by the preparation of the leaf.

So, manufacturers can reliably distinguish types and batches of tea leaves by measuring their color. This ensures that their batches have been processed correctly. Finally, it guarantees consistency batch to batch over commodity-scale quantities and decades of production.

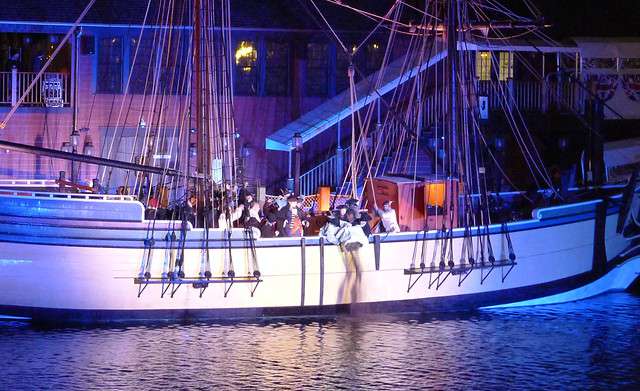

Without accurate, objective analysis, manufacturers will lose revenue. Batches of tea that fail to meet client standards for consistency and quality can be rejected. Repeated failures can cause clients to begin looking for other manufacturers. Likewise, failing to detect a processing error, such as a mistake in drying temperature or timing, can damage entire batches. It’s unlikely any single error will be harmful to a manufacturer as losing 46 tons of tea, around $1.7 million in today’s dollars, was to the British East India Company. Over years, a manufacturer’s small losses can easily add up to a greater total amount of lost tea than in the Boston Tea Party. To avoid this, manufacturers use spectrophotometric analysis to eliminate measurement errors. It’s easier than going to war.