Peanuts are a major agricultural product around the globe. From shelled, to roasted, to crushed and pureed, peanuts are a great snack food and used in many other food products as well. Image Source: Flickr user USDAgov

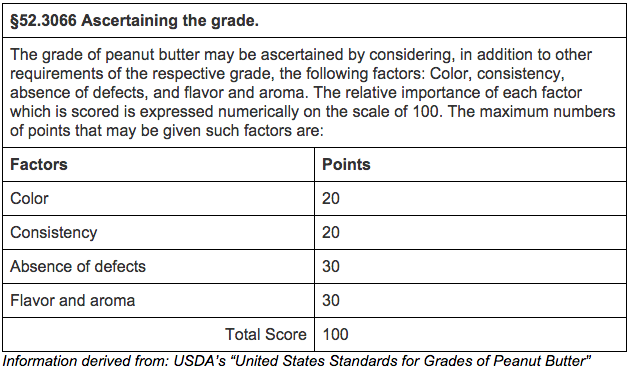

Peanuts are a major agricultural crop all around the world. Nearly 50% of all shelled peanut products in the United States are processed into peanut butter, and development of this popular commodity depends on spectral analysis for the best visual quality and taste. Perhaps it is already apparent how color measurement would affect the appearance of peanut butter products, but maybe even more important is how the color of roasted peanuts correlates with flavor.

Spectral analysis refers to the use of light to differentiate the color in various sample materials and quantify this data for quality analysis or reproduction purposes. This process is extremely important when dealing with food products that require multiple stages of preparation, especially products which are roasted during the processing phase. Spectral analysis during roasting of products, such as coffee beans, helps to determine the final color result and also helps to determine the flavor outcome. This is also true in roasting peanuts. No matter what peanut variety is used, common roasting practices and overall color measurement stability will help ensure a quality product that meets the standards in both appearance and taste.