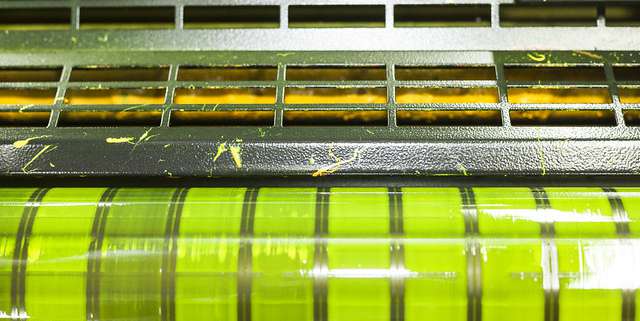

Offset ink analysis is essential for top quality products and performance in today’s high-speed production printing industry. Image Source: Flickr’ user Remy CARTERET

Today’s printing industry is booming and production rates are reaching record level speeds as offset printers race to match supply with demand. Much like the benefits of high-octane fuel in a fast little sports car, press operators rely on high-performance ink quality to reach top speeds and maintain customer satisfaction.

Instrumental analysis is an important element in laboratory ink production and necessary for predicting various performance outcomes. Variables such as high-level press speeds and the many variations in substrates used in today’s commercial labels and packaging all create challenges in offset ink performance. According to Ink World Magazine, “assessing printing characteristics is critical to determining how ink is likely to perform, and having standard equipment is essential. Without these instruments or procedures, an ink company would have a difficult time ensuring its products perform on press. In addition, an excellent ink laboratory can help when troubleshooting is required”1. Developing standards and procedures for ink specifications and quality starts with advanced instrumentation. Spectrophotometers offer a variety of analytical options to ensure accurate color matching and consistency. One small yet effective tool can accomplish a variety of tasks and is a must for any ink laboratory.

Analysis of ink concentration levels effects production quality and performance and is necessary for maintaining quality control. Image Source: Flickr’ user Remy CARTERET