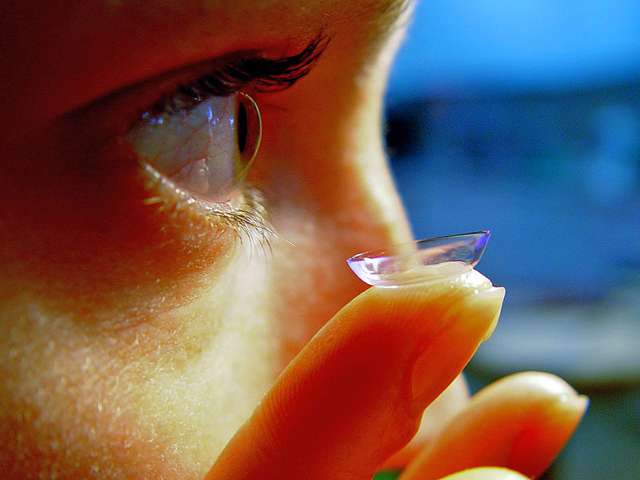

Spectrophotometers can help you determine how translucent or opaque your contact lens pigmentation is, improving quality. Image Source: Unsplash user Daniil Avilov

Using colored contact lenses, a professional cosplayer is able to completely transform her appearance within seconds. One moment, she’s a brunette with rich brown eyes. But after popping on a pair of bright purple contact lenses (with a wig to match), she suddenly transforms into a cartoonish alien character that barely resembles herself.

Since the invention of cosmetic colored contact lenses in 1969, cosplayers, makeup artists, Halloween trick-or-treaters, and everyday contact lens users have used colored contacts to alter their original eye color.1 However, in order to completely cover someone’s natural eye color, these contact lenses need to have enough pigment to hide the iris’ original hue. This can be a complicated and difficult process for manufacturers; if they don’t inject enough pigment into the lens, the final effect will look muddy while injecting too much may look unnatural. Even if you’re making semi-translucent lenses that are only meant to enhance the wearer’s natural eye color, pigment accuracy is still vital. You have to ensure that the colors look subtle, appealing, and completely natural. Analyzing your lenses using spectrophotometric instrumentation helps you achieve the perfect pigment balance to ensure your customers can create their ideal look.

Unusual patterns are almost always made using fully-opaque contact lens dyes. Image Source: Wikimedia user Anime Evolution