How Is Ketchup Made?

The process of tomato ketchup manufacturing begins with quality tomatoes. Tomato color and grade is important, since red, quality tomatoes will produce the bright red color of ketchup. Manufacturers also subject their raw materials to a strict tomato quality evaluation. Variations in tomato quality can produce inconsistency in the final product's look.

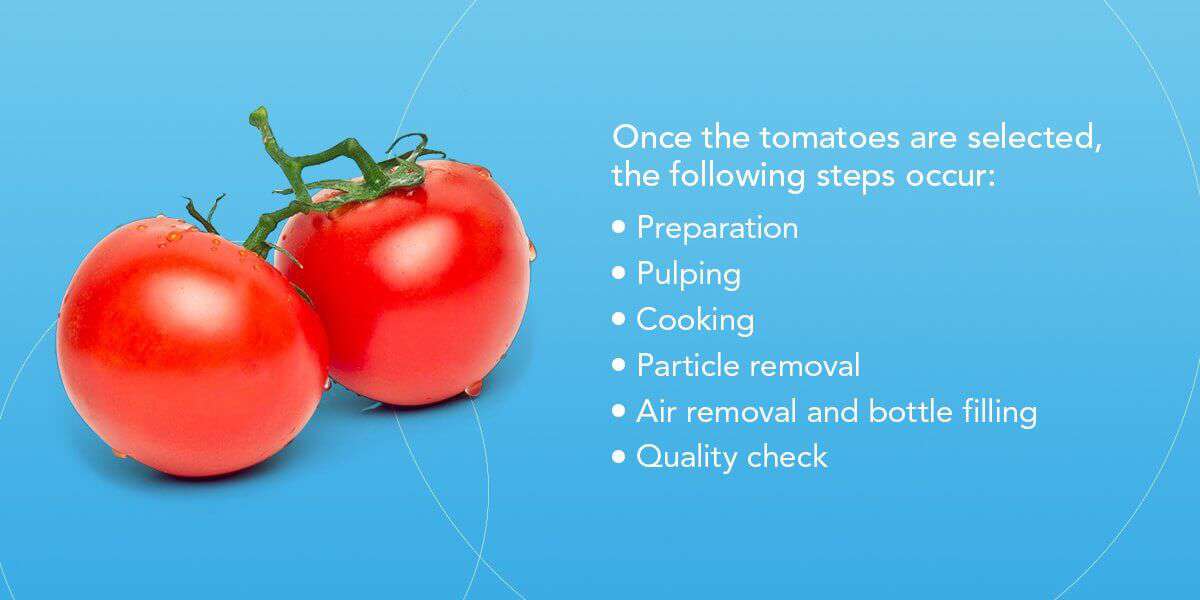

Once the tomatoes are selected, the following steps occur:

- Preparation: The tomatoes are sorted, cleaned, and cut before they are precooked in large vats to kill any bacteria.

- Pulping: The tomatoes are then placed in pulping machines so the pulp and juice can be extracted and filtered. The resulting filtered tomato juice and pulp can be made into paste for later ketchup manufacturing or immediately processed into ketchup.

- Cooking: The pulp is heated in cooking tanks and ingredients are added, such as flavorings, salt, vinegar, spices, and sweeteners. For the best ketchup, manufacturers measure ingredients precisely and time their cooking for the optimal flavor, texture, and color. Cooking the ketchup allows the ingredients to absorb.

- Particle removal: Then, the cooked mixture passes through finishing machines to remove any particles.

- Air removal and bottle filling: The ketchup has excess air removed to prevent air pockets and bacteria growth, then passes to filling machines that transfer it into containers. The containers are sealed quickly to maintain freshness.

- Quality check: The containers are then cooled and labelled before going through any final quality check process a manufacturer may have.

How Tomato Color Analysis Helps Ketchup Manufacturers Meet Quality Standards

The U.S. Department of Agriculture (USDA) publishes standards for tomato ketchup grades:

- U.S. Grade A. This ketchup contains few or no defects. It has good color, consistency, flavor, and finish. It must have a total solids content of at least 33% by weight.

- U.S. Grade B. This ketchup contains few or no defects. It has good color, consistency, flavor, and finish. It must have a total solids content of at least 29% by weight.

- U.S. Grade C. This ketchup is generally free from defects. It must have “fairly good” color, consistency, and flavor. It must have a good finish and a total solids content of at least 25% by weight.

The USDA standards for ketchup also require ketchup to be graded on a scale of 100, with 25 points being allocated for color. U.S. Grade A has a score of at least 85. According to the USDA, good color, which adds up to 25 points to the score, comes from ripe, high-quality tomatoes that are correctly processed. The standard uses Munsell color discs to evaluate the exact color quality of ketchup.

It takes 148 grams of tomatoes to make 100 grams of ketchup. Any difference in the quality of tomatoes can impact the final condition of the ketchup, so selecting the deepest red tomatoes can create a richer ketchup color.

It’s also important for manufacturers to choose a consistent tomato color so the finished ketchup is the hue customers expect. When all containers of ketchup on a shelf are the same color, customers may feel more confident about the product's quality and consistency.