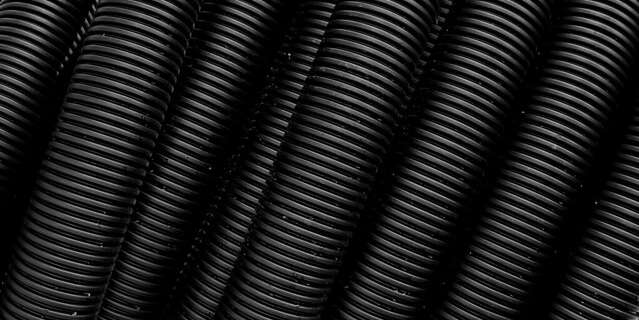

Carbon black is one of the most commonly used additives to both commercial and industrial grade plastics. Used as both a base of color comparison as well as a UV absorption material to increase durability, the color measurement of carbon black filled plastics is an important part of polymer production. Image Source: Flickr user Jori Samonen

Plastic is one of the most versatile materials available. With the ability to be molded and formed into nearly any shape, size, or color the possibilities are nearly endless. Yet manufacturers continually struggle with achieving color consistency and maintaining durability and UV resistance. Carbon black plastic technology is a preferred method for increasing the strength and stability of these products and can be used for a variety of applications. The color measurement of carbon black filled plastics provide the data needed to monitor various color changes as well as the UV resistance qualities in plastic materials. This process begins with the dry blending of carbon black and the primary resin, where color analysis starts prior to molding in order to achieve the right balance in color and stability.