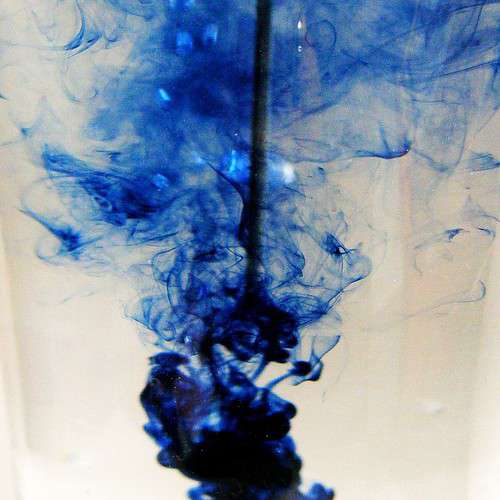

Thermochromic responses to temperature variations offer exciting possibilities for product packaging across industries. Image Source: Flickr user Claudio Matsuoka

When I was in the sixth grade, one of the most valuable status symbols a person could possess was a Hypercolor shirt. The t-shirts were nothing special in terms of cut or style and, in retrospect, they were quite unattractive. But what made them so alluring and coveted was their thermochromism—the ability to shift color depending on the temperature—which provided endless entertainment for easily impressed 11-year-olds. Along with sprayed bangs and stirrup pants, these were must-have items.

Today, thermochromic inks and dyes go beyond influencing the social lives of pre-teen girls through questionable fashion choices. Advanced color-changing materials are quickly becoming an integral part of intelligent packaging designs that not only enhance marketability, but improve consumer experiences and offer ingenious health and safety safeguards. The development of packaging with thermochromic elements relies on accurate, objective color measurement to unlock the potential of these innovative materials.

Beer manufacturers use color-changing labels that react to cold temperatures to strengthen brand identity and expand market share. Image Source: Pexels