Color is one of the first sensory processes humans experience. It can alert us to potential danger, like the orange of a safety cone, or tell us what flavor we might expect from a piece of candy.

Long-term changes to color appearance can have negative impacts — a dusty pink fire engine isn't going to draw attention as effectively as a bright red one. Learning about color stability and understanding its importance, challenges, and the best way to ensure it can help you prevent unwanted deviations from the intended, expected, and desired results.

Defining the Stability of Color

In its simplest terms, color stability refers to how well a material can maintain a consistent color throughout its life span.

It's important to note that color stability substantially differs from color consistency and constancy. While maintaining those traits is also vital, these terms refer more to eliminating chromatic variations across batches, production lines, facilities, and observation conditions like illumination.

Factors That Can Impact Color Stability

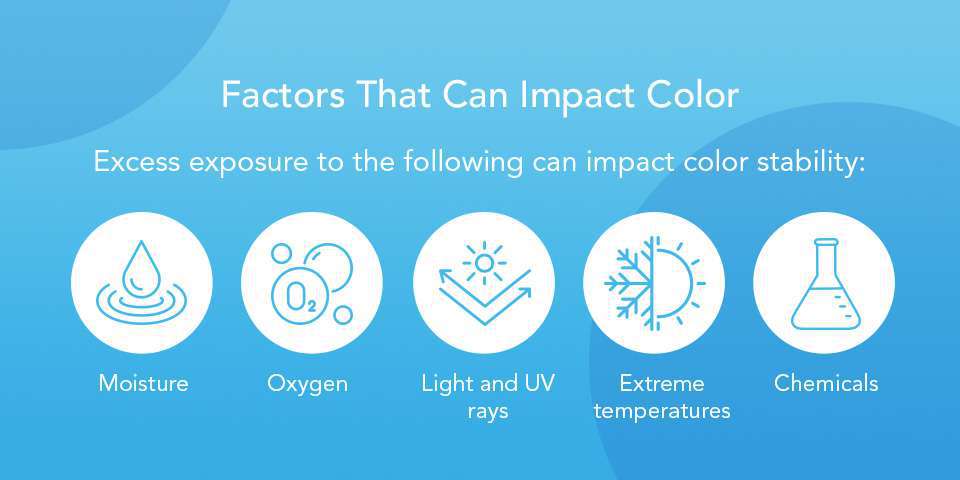

Multiple factors can cause alterations in chromaticity as time passes. As a result, changes can arise during any manufacturing stage and throughout material storage and distribution. Excess exposure to the following can impact color stability:

- Moisture

- Oxygen

- Light and UV rays

- Extreme temperatures

- Chemicals

The Importance of Color Stability

Maintaining color over time is vital for several reasons.

Quality

Color and quality are inherently intertwined. Chromaticity that meets a consumer's expectations encourages them to form a positive brand image. When color conforms to industry standards, it also showcases your company as one committed to best practices. Color stability helps support these outcomes by ensuring long-lasting durability, which boosts perceived value.

Safety and Compliance

In many products, color stability goes hand in hand with safety. Consider goods like reflective safety tape, camouflage military uniforms, and edible oils, where color alterations over time can impact visibility or indicate potential contamination that would make it unsafe for consumption. Additionally, products whose color maintains acceptable tolerances in highly regulated industries prevent unnecessary fines or penalties.

Appeal

Customers may see color as the primary determinant in their purchasing decisions for certain items, like vinyl siding and roofing shingles. Remodeling a home exterior is a significant investment that consumers expect to last for years. Customers don't just want it to look good now — they want to know the color they see at first is the color they can expect it to stay, even after long-term exposure to the elements.