The Yellowness Index from ASTM International provides a measurable standard for assessing the yellowness in white or light-colored materials, such as plastics. This standard determines the degree of yellowness present, allowing companies to perform quality control processes to maintain product consistency. The test uses a spectrophotometer to quantify the color measurement.

The APHA color system is the most common measurement scale for measuring yellowness in liquids. It serves industries ranging from chemical production to pharmaceutical development.

Materials That Require Yellowness Observations

Various plastics require yellowness observations due to the changes these materials undergo in processing. These plastics include:

- Polyvinyl chloride (PVC)

- Polycarbonate (PC)

- Purified terephthalic acid (PTA)

- Polyethylene terephthalate (PET)

Yellowness appears in PET due to oxidation. With the increasing use of recycled PET (rPET), manufacturers must measure color to counter yellowness and determine the correct ratio of optical brighteners required to mitigate it.

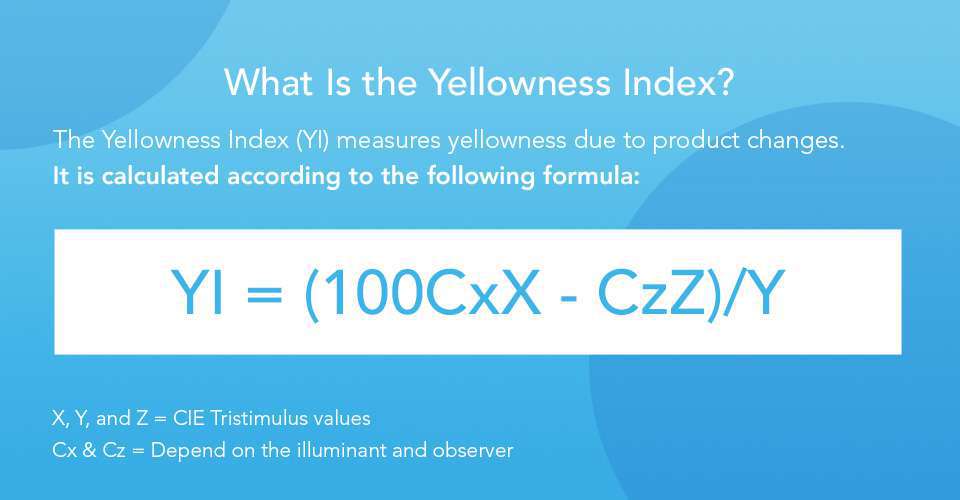

What Is the Yellowness Index?

The Yellowness Index (YI) measures yellowness due to product changes. The ASTM E313 Yellowness Index is the most common method for determining yellowness in materials like plastics. The standard gives defined indices for measuring the shift from ideal white. It is calculated according to the following formula:

YI = (100CxX - CzZ)/Y

The X, Y, and Z variables are CIE Tristimulus values, which express color and how it is perceived. Cx and Cz depend on the illuminant and observer. During calculations, users choose the values for these coefficients from a table to correspond with spectrophotometer settings. The ASTM E313 combines the calculations into a single value, defining the yellowness amount in a sample. The lower the number, the less yellow the material is.

The YI value is commonly reported as the difference in yellowness between a product sample and the original or reference, designated as delta YI (∆YI).